BPH Series Horizontal Metal Chips Briquetting Press Machine mainly compress metal chips such as meta...

| Basic Infomation | |

Packaging: Nude Packing Steel Plate: Q235B Special Design: Pre-Press Design Conveyor: Yes, Provided Package: Plastic Films/Nude Package Brand: Diloya Payment Term: T/T L/C Model Series: BPP Series Control: PLC Automtic Control Lead Time: 15 Days | Bale Density: 2000-7500kg/m³ Driven Type: Hydraulic Driven Color: Ral5013 or Per your requirement Motor Power: 15-60kw Model Series: BPD Series Electrical Components: Schneider Supply Ability: 50-100sets/Month Test Video Before Shipment: Provide Applicable Material: Various of metal chips Productivity: 30-50sets/Month |

| Additional Information | |

Place of Origin: China Warranty Time: 1 Year Certificate: CE TUV ISO Delivery Time: 30 Days | Working Pressure: 21.5Mpa Bale Weight: 1.5-12kg Quality Control: ISO9001, 2008 Core Components: Pump, Motor |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

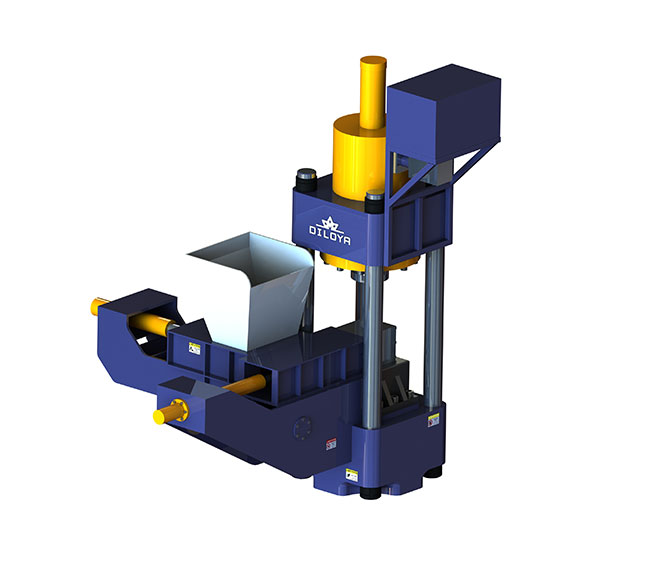

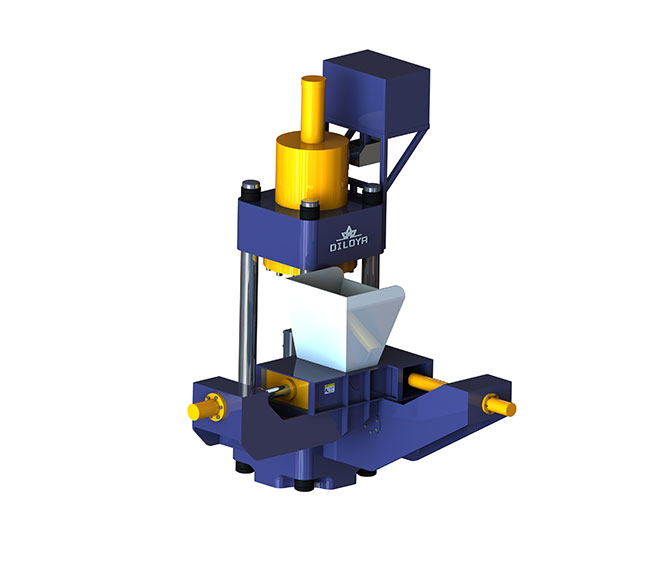

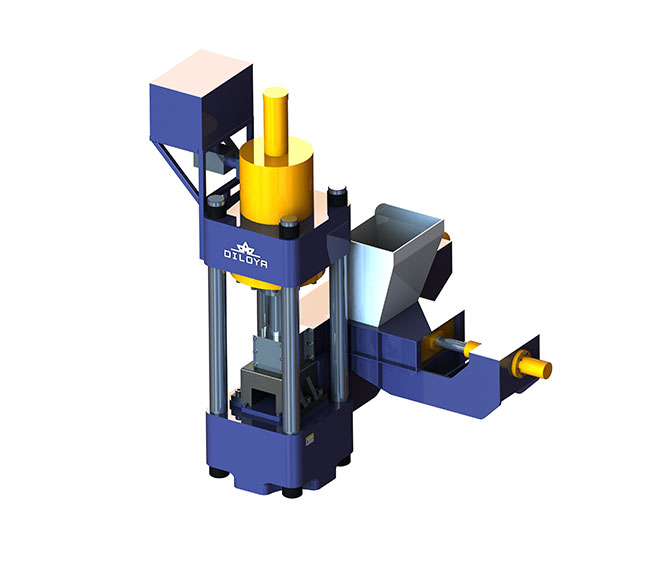

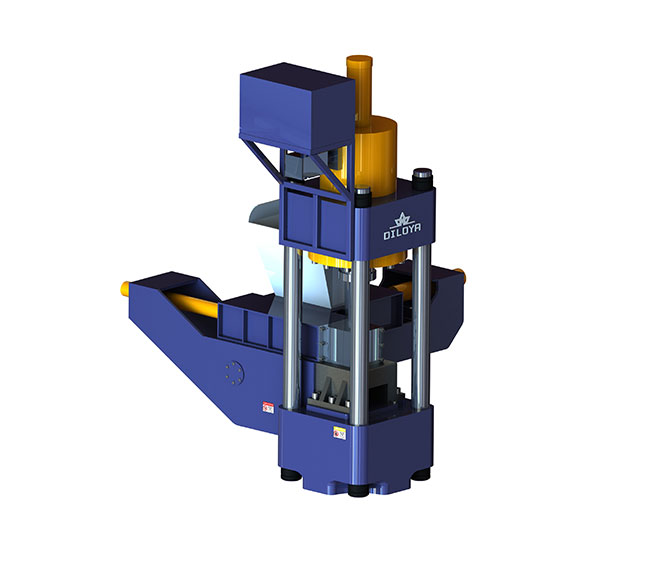

BPP Series Metal Chips Briquetting Press Machine mainly compress metal chips such as metal shavings, copper shavings, copper swarfs, brass chips, copper turnings, aluminum chips, aluminum shavings, cast iron chips, various of loosen metal chips etc...

The BPP Series Metal Chips Briquetting Press Machine mainly used in steel manufacturer and many waste disposal recycling center, it is composed of three sections: hydraulic system, electrical system, main frame, automatic PLC control or manual control, more optional choice for you, can compress many materials such as metal scrap, aluminum scrap, stainless scrap, copper scrap, all kinds of ferrous and non-ferrous metals shavings, chips, turnings, borings, etc.

Working Principle: The metal chips is put into the hopper by conveyor, then the main cylinder start to press the chips to limit of the non-ferrous metal chips baling press machine, the side cylinder push the briquette out, and last, every cylinder back to initial position, the bale cycle is finished totally.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BPP150 | Φ100X(50-80) | 1-1.5 | 15 |

BPP200 | Φ120X(50-100) | 1.8-2.5 | 18.5 |

BPP250 | Φ140X(80-120) | 2.4-3.6 | 22 |

BPP315 | Φ150X(100-140) | 4-5.6 | 30 |

BPP360 | Φ160X(100-140) | 4.5-6.5 | 30 |

BPP400 | Φ180X(100-160) | 5-7.1 | 37 |

BPP500 | Φ200X(100-160) | 6.3-9.5 | 22X2 |

BPP630 | Φ220X(120-180) | 9.1-12.5 | 30X2 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

1. Adopts vertical simple structure, stable and reliable.

2. Easy to operate and maintain, save stock cost and labor cost, transport cost, space etc.

3. Automatic PLC control, high efficiency, high density of bale after briquetting is easy to remelt, and production rate is very high.

4. Output capacity varies from 500-5000 kg per hour, more options for your choices.

5. Latest design of pre-press system, one time one bale more efficiency.

6. Bale output capacity can be up to 300 bales per hour, more efficient.

7. Adopts German Hydraulic technology to promise the machine run smoothly and stable.

8. Adopts international famous brand of hydraulic pump and valves.

9. Lower price, economical option for your business, it's ideal briquetting press machine for your choices.

Application

The baler machine can press below materials:

|  |  |  |

| Metal Chips | Bronze Chips | Brass Chips | Copper Shavings |

|  |  |  |

| Iron Cast Chips | Aluminu Shavings | Copper Chips | Stainless Steel Chips |

FAQ

> Do you have a customer case of High quality aluminum Borings briquette machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> Do you have a agent of China aluminum Borings briquetting machine in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is package of High Density Aluminum Drillings briquette machine?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> Which country have you exported the Y83 Aluminum Drillings briquetting press?

We have exported the bbriquetting press machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> What are all the skills required to operate a Automatic baler for Aluminum swarfs manufactured by Diloya?

No special skills, just read the user manual carefully before operating the briquetting press machine, if you have any questions, feel free to contact with us, we can help you at any time.

> What is High density aluminum Shavings briquetting press?

The machine is mainly used to compress steel chips, aluminum chips, brass chips, stainless steel chips bronze shavings, copper shavings, etc into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for metal manufacturer to meal again, improve the product rate.

> Is your price of Vertical block making machine for Aluminum borings competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as sinobaler, nk baler, skbaler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Where to find cheap China Aluminum turnings block making machine?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> How much price of SBJ aluminum Swarfs baler?

Price of the machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> What is payment term of Automatic Aluminum Drillings briquetting press?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China

Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China