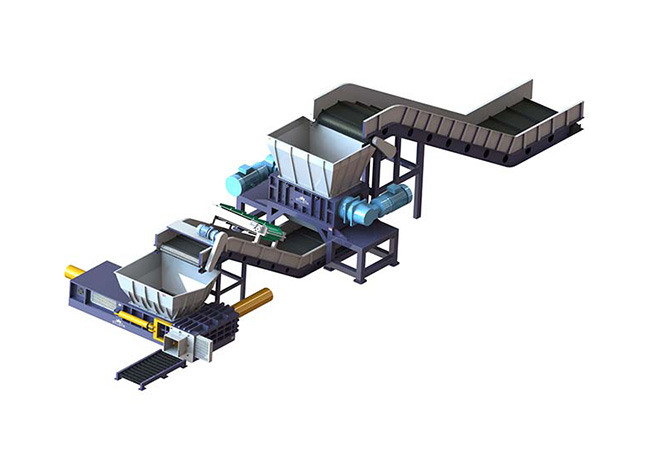

A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

Steel Plate: Q235B; | Color: Ral5013 or Per your requirement; |

| Additional Information | |

Hydraulic Power: 1250-6300kn; | Voltage Frequency: 50HZ/60HZ; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

A 360-ton brass chips briquetting press machine is a heavy-duty industrial equipment designed to compress loose brass chips or turnings into dense, solid briquettes. This process not only makes the material easier to handle and transport but also facilitates its recycling and reuse.

Here are some key points about this type of machine:

Key Features:

1.Pressing Force: The 360-ton capacity refers to the maximum force that the machine can apply to compress the brass chips. This high force ensures that even tough materials like brass can be effectively compacted.

2.Material Handling: The machine is designed to handle large volumes of brass chips, which are often produced as a byproduct in machining and manufacturing processes.

3.Briquette Quality: The resulting briquettes are typically uniform in size and density, making them ideal for further processing or recycling. They can be easily stored and transported, reducing the risk of fire hazards and improving overall safety.

4.Automation and Controls: Modern briquetting presses often come with advanced control systems, including PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for easy operation and monitoring.

5.Safety Features: These machines are equipped with various safety features such as emergency stop buttons, safety guards, and interlocks to protect operators and prevent accidents.

Applications:

-Recycling Industry: Brass briquettes can be sold to smelters and foundries for recycling, reducing waste and environmental impact.

-Manufacturing Plants: Companies that produce brass parts can use these machines to manage their scrap material more efficiently.

-Metal Processing: Briquetting can help in the recovery of valuable metals from brass chips, which can then be used in new production processes.

Benefits:

-Cost Savings: Reducing the volume of brass chips can lower storage and transportation costs.

-Environmental Impact: By recycling brass, the need for raw materials and energy-intensive extraction processes is reduced.

-Improved Efficiency: The compacted briquettes are easier to handle and can be processed more efficiently in downstream operations.

Maintenance and Operation:

-Regular Maintenance: Regular cleaning and lubrication of moving parts are essential to ensure the machine operates smoothly and to extend its lifespan.

-Operator Training: Proper training for operators is crucial to ensure safe and efficient operation of the machine.

-Wear Parts: Components such as dies and punches may need periodic replacement due to wear and tear.

If you are considering purchasing a 360-ton brass chips briquetting press machine, it's important to evaluate your specific needs, such as the volume of brass chips you generate, the desired output, and the available space for the machine. Consulting with a reputable manufacturer or supplier can help you make an informed decision.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP250 | Φ100X(50-80) | 2.3-3.2 | 22 |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Schneider electrical components prolong the service life of the machine.

> Enough spare parts with lower cost to keep the machine non-stop.

> Adopts pre-press structure to keep high output capacity with high density.

> Latest design of the machine to let you use the best the machine all the time.

> Adopts china famous pump to keep baler machine run smoothly.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

|  |  |  |

FAQ

> What is payment term of Casting chips Copper Briquette press?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How to maintain Brass turnings briquetter?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> What profits can we get from the Scrap Metal Chips Hydraulic Briquetting Press Machine?

You need to know price of metal chips, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

> Is your price of Brass borings baling machine competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as eco baler,Wanshida baler, TF Baler, Gaode Baler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Do you provide video support of Y83-250 Metal Chips Briquetting Press?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> How can we install the Brass turnings briquette machine?

The machine is marked tips when shipping, and you can easily assemble the machine per the tips, after assembling, put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is ok, if you have any questions, you can contact with us any time.

> What is Metal Chip Briquetter With Oil Collection?

The machine is mainly used to compress steel chips, aluminum chips, brass chips, stainless steel chips bronze shavings, copper shavings, etc into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for metal manufacturer to meal again, improve the product rate.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China