A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

Hydraulic Power: 1250-6300kn; | Bulk Density: Up to 7t/m3; |

| Additional Information | |

Bale Shape: Cylindrical; | Motor Brand: Taizhou Taida; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

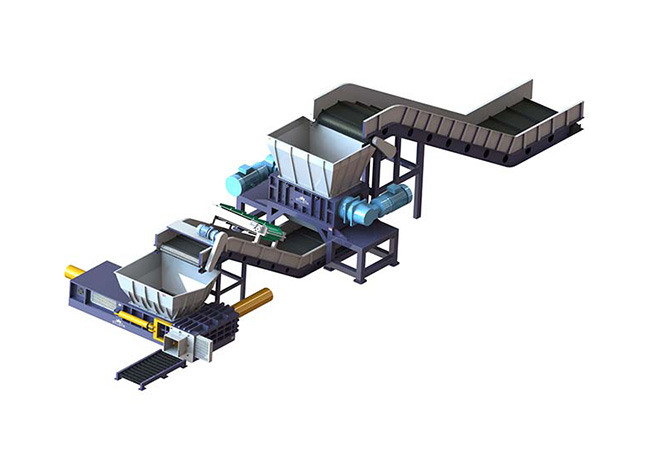

An automated metal powder briquette pressing machine for copper is a specialized piece of equipment designed to compress copper powder into solid, compact briquettes. This process is crucial in various industries, including metallurgy, recycling, and manufacturing, where it's necessary to handle, store, or further process metal powders efficiently.

Here are some key aspects of such a machine:

Components and Features

1.Feeding System: -Hopper: A container that holds the copper powder. -Conveyor or Screw Feeder: Transports the powder from the hopper to the press.

2.Pressing Unit: -Hydraulic Press: Uses hydraulic pressure to compress the powder. -Die and Punch: The die is the mold into which the powder is pressed, and the punch applies the force to compress the powder.

3.Control System: -PLC (Programmable Logic Controller): Manages the entire process, ensuring precise control over the pressing parameters. -HMI (Human-Machine Interface): Allows operators to set and monitor the machine's settings and performance.

4.Ejection Mechanism: -Automatic Ejector: Pushes the formed briquette out of the die after pressing.

5.Safety Features: -Emergency Stop: Immediately halts the machine in case of an emergency. -Safety Guards: Protects operators from moving parts and high-pressure areas.

Benefits

-Efficient Handling: Briquettes are easier to handle, transport, and store compared to loose powder.

-Reduced Waste: Minimizes dust and waste, improving material utilization.

-Consistent Quality: Ensures uniform density and size of the briquettes, which is important for downstream processes.

-Automation: Reduces labor costs and increases production efficiency.

Applications

-Recycling: Processing scrap copper for reuse.

-Metallurgy: Preparing copper powder for sintering or other metallurgical processes.

-Manufacturing: Producing copper components for various industrial applications.

Operating Steps

1.Loading: Copper powder is loaded into the hopper.

2.Feeding: The powder is conveyed to the pressing unit.

3.Pressing: The hydraulic press compresses the powder into a briquette.

4.Ejection: The formed briquette is ejected from the die.

5.Collection: The briquettes are collected and prepared for further processing or storage.

Maintenance and Safety

-Regular Maintenance: Ensure the machine is well-maintained to prevent breakdowns and ensure safety.

-Operator Training: Train operators on proper use and safety procedures.

-Wear and Tear: Regularly inspect and replace worn-out parts, such as the die and punch.

Considerations for Purchase

-Capacity: Choose a machine with the appropriate capacity for your production needs.

-Customization: Some manufacturers offer customization options to meet specific requirements.

-Support and Service: Look for a supplier that offers good after-sales support and service.

If you have any specific questions or need more detailed information about a particular model or brand, feel free to ask.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP150 | Φ70X(40-60) | 1-1.8 | 15 |

BP200 | Φ80X(40-70) | 1.2-2.8 | 18.5 |

BP250 | Φ100X(50-80) | 2.3-3.2 | 22 |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Can press varous of metal chips, aluminum shavings, copper granules, bronze chips, brass shavings etc...

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Latest design of the machine to let you use the best the machine all the time.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Output capacity can be up to 200-300bales per hour, more efficient.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

> Schneider electrical components prolong the service life of the machine.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

|  |  |  |

FAQ

> Do you have a customer case of Bronze turnings block making machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> Do you provide video support of Metal Turning Scrap Briquetting Compactor?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> How can we install the Brass millings baling machine?

The machine is marked tips when shipping, and you can easily assemble the machine per the tips, after assembling, put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is ok, if you have any questions, you can contact with us any time.

> What profits can we get from the Vertical Hydraulic Al Briquette Briquetting Press Machine?

You need to know price of metal chips, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

> Where to find cheap Copper Swarfs briquetter?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> How can i know you are a manufacturer or trader of Brass borings briquette machine?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> How to maintain Metal Chip Briquetting Presses?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> What all do I need to install the Metal Swarf Shredder Briquettes Line?

After the briquetting press machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the machine per user manual, or make video call with our engineer.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China