A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

Price of Machine: Depends on Models; | Oil Tank Volume: 600-2400L; |

| Additional Information | |

Bale Shape: Cylindrical; | Discharge Out: Automatic Continuous Out; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

A Copper Scrap Chips Briquetting Press is a machine used to compress loose copper scrap chips or turnings into dense, compact briquettes.

This process offers several benefits, including:

1.Volume Reduction: Compressing the scrap reduces its volume, making it easier and more cost-effective to transport and store.

2.Recycling Efficiency: The briquettes are more manageable and can be fed into smelting furnaces more efficiently, improving the recycling process.

3.Reduced Handling Costs: Briquettes are easier to handle and load into trucks or containers compared to loose scrap.

4.Environmental Benefits: By reducing the volume of scrap, the press helps in minimizing the environmental impact associated with transportation and storage.

Key Features of a Copper Scrap Chips Briquetting Press

-High Pressure: These machines use high pressure (often in the range of 1000-3000 kg/cm²) to compress the scrap into briquettes.

-Hydraulic System: Most briquetting presses use hydraulic systems to generate the necessary pressure.

-Automation: Many modern presses are automated, with features like automatic feeding, pressing, and ejection of briquettes.

-Safety Features: Equipped with safety mechanisms to protect operators and ensure smooth operation.

-Customizable: Some models allow for customization to suit specific requirements, such as different sizes and shapes of briquettes.

Types of Copper Scrap Chips Briquetting Presses

-Vertical Presses: These are typically used for smaller operations and can produce briquettes of various sizes.

-Horizontal Presses: Suitable for larger-scale operations, these presses can handle higher volumes of scrap and often have higher production capacities.

Applications

-Metal Recycling Plants: Used to process and prepare scrap for recycling.

-Manufacturing Facilities: To manage and recycle in-house scrap generated during manufacturing processes.

-Scrap Dealers: To increase the value of scrap by making it easier to handle and transport.

Maintenance and Operation

-Regular Maintenance: Regularly check and maintain the hydraulic system, lubrication, and wear parts to ensure optimal performance.

-Operator Training: Ensure that operators are properly trained to use the machine safely and efficiently.

-Material Preparation: Properly sort and clean the scrap before feeding it into the press to avoid contamination and ensure consistent quality of briquettes.

If you are considering purchasing a Copper Scrap Chips Briquetting Press, it's important to evaluate your specific needs, such as the volume of scrap, desired briquette size, and budget, to choose the right model. Consulting with a supplier or manufacturer can also provide valuable insights and help you make an informed decision

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

BP800 | Φ200X(100-160) | 13.5-18.6 | 2x45 |

If you have any special requirements, we will customize according to your special needs.

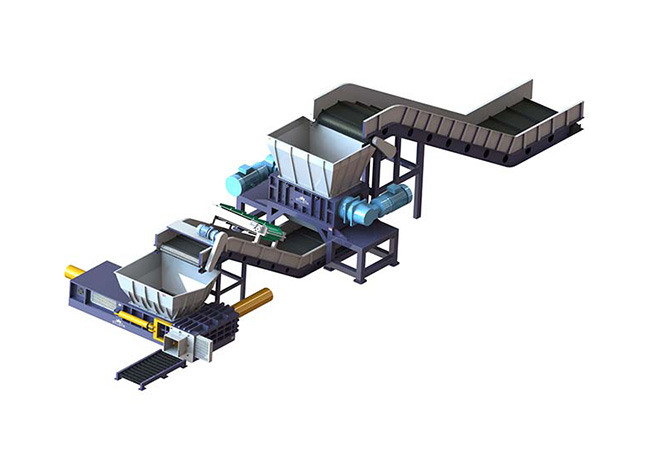

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Can press varous of metal chips, aluminum shavings, copper granules, bronze chips, brass shavings etc...

> Stable hydraulic system to keep the machine run well.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

> Adopts high speed structure to reduce cycle time for every one bale.

> Schneider electrical components prolong the service life of the machine.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Enough spare parts with lower cost to keep the machine non-stop.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

|  |  |  |

FAQ

> How can i know you are a manufacturer or trader of Metal Chip Scrap Block Briquetting Machine?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> What is warranty time of the Copper Scrap chips Briquetting Press?

The warranty time of the briquetting press machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> Do you provide video support of Metal Scrap Chip Briquetting Press Machine?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> What is payment term of Copper Briquette Casting Press?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How to maintain Aluminium Turning Scrap Baling Machine?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Where to find cheap Iron Dust Briquette Machine?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> What profits can we get from the Brass Swarfs baling machine?

You need to know price of metal chips, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China