A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

Monthly Throughput: 500-3000tons; | Model Series: BPP Series; |

| Additional Information | |

Bale Shape: Cylindrical; | Control: PLC Automtic Control; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

An Iron Briquetting Machine, also known as a Scrap Copper Chip Briquette Press, is a type of equipment used in the metal recycling and processing industry. This machine compresses loose metal chips, such as iron or copper, into dense, compact briquettes. The process not only reduces the volume of the scrap but also makes it easier to handle, transport, and store. Additionally, the briquetting process can help in recovering any cutting fluids or lubricants that may be present in the metal chips, which can then be reused or properly disposed of.

Key Features and Benefits:

1.Volume Reduction: Significantly reduces the volume of scrap metal, making it more efficient to store and transport.

2.Recovery of Cutting Fluids: Helps in separating and recovering valuable cutting fluids, reducing waste and saving costs.

3.Improved Handling: Briquettes are easier to handle and load into furnaces for melting, compared to loose chips.

4.Higher Recycling Value: Briquetted metal is often more valuable than loose chips because it is denser and easier to process.

5.Environmental Benefits: Reduces the environmental impact by minimizing waste and improving the efficiency of metal recycling processes.

Types of Briquetting Machines:

-Hydraulic Briquetting Machines: Use hydraulic pressure to compress the metal chips. These are common and can handle a wide range of materials.

-Screw Presses: Use a screw mechanism to compress the material. They are typically used for smaller volumes and softer materials.

-Roller Presses: Use two or more rollers to compress the material. These are often used for high-volume production and can handle harder materials.

Applications:

-Metal Recycling Facilities: For processing and compacting scrap metal.

-Manufacturing Plants: To manage and recycle metal chips produced during machining processes.

-Casting and Foundry Operations: To prepare metal chips for re-melting and casting.

Considerations When Choosing a Briquetting Machine:

-Material Type: Ensure the machine is suitable for the type of metal chips you will be processing (e.g., iron, copper, aluminum).

-Capacity: Choose a machine that can handle the volume of material you need to process.

-Power Requirements: Consider the energy consumption and ensure it fits within your operational budget.

-Maintenance and Support: Look for machines with good after-sales support and easy maintenance.

If you have specific requirements or need further information on a particular model, feel free to provide more details, and I can offer more tailored advice

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP150 | Φ70X(40-60) | 1-1.8 | 15 |

BP200 | Φ80X(40-70) | 1.2-2.8 | 18.5 |

BP250 | Φ100X(50-80) | 2.3-3.2 | 22 |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

If you have any special requirements, we will customize according to your special needs.

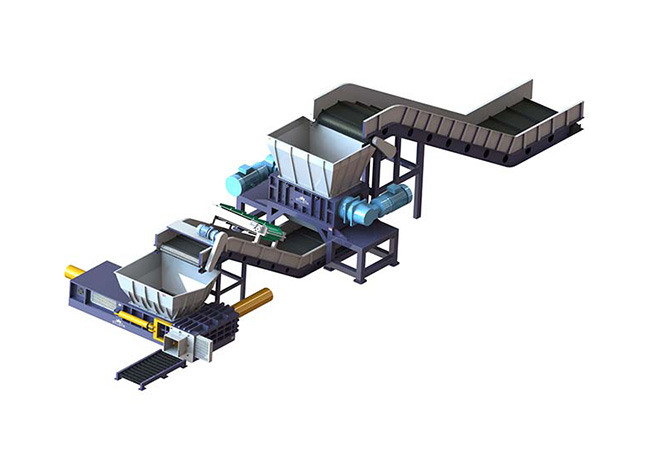

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

1> World famous brand of Siemens PLC to promise you run the machine without any worry.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Adopts pre-press structure to keep high output capacity with high density.

> Lifelong after services let you have no any concern, get more porfits.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Schneider electrical components prolong the service life of the machine.

> Latest design of the machine to let you use the best the machine all the time.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

|  |  |  |

FAQ

> What is payment term of Metal Powder Briquetting Machine?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How can i know you are a manufacturer or trader of Scrap Metal Chip Briquetting Compresser?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> What is after-services of Tcm Baler Aluminum Chips Briquetting Machine?

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the machine for free, which also include video support, email services, and in a word, we can get everything done.

> Where to find cheap Steel Powder Hydraulic Briquet Press Ato Feeding System?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> Are you a manufacturer or a trader of Where To find A Hydraulic Powder Briquetting machine?

We are true manufacturer of briquetting press machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> What are the service requirements of the Waste Metal Chip Briquetting Press?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> What profits can we get from the Briquetting Metal Chips Machine?

You need to know price of metal chips, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China