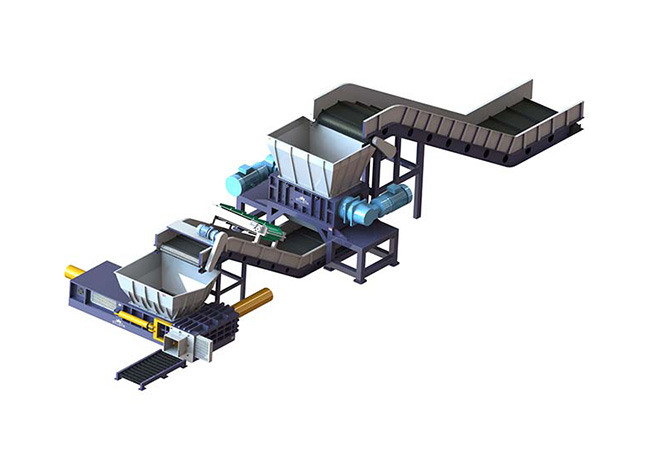

A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

Productivity: 30-50sets/Month; | Shipping Time: 10-50days; |

| Additional Information | |

Special Design: Shear Baler; | Feed Hopper Size: 1500x1200mm; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

A Baler Stainless Steel compactor machine is a type of equipment used to compress and compact various materials, such as scrap metal, cans, and other recyclable waste, into dense bales or blocks. This process makes the materials easier to handle, store, and transport, and it also helps in maximizing the space utilization in recycling facilities and reducing transportation costs.

Key Features:

1.Stainless Steel Construction: The use of stainless steel ensures durability, corrosion resistance, and longevity, making the machine suitable for harsh environments.

2.High-Pressure Compaction: These machines can apply significant pressure to compress materials, resulting in highly compacted bales.

3.Versatility: They can handle a variety of materials, including aluminum cans, plastic bottles, cardboard, and more.

4.Efficiency: Modern balers are designed to be energy-efficient and can process large volumes of material quickly.

5.Safety Features: Equipped with safety mechanisms to protect operators, such as emergency stop buttons and safety guards.

6.Ease of Use: Many models come with user-friendly controls and automated processes to simplify operation.

7.Customization Options: Some manufacturers offer customization options to meet specific needs, such as different bale sizes and shapes.

Applications:

-Recycling Facilities: For processing and compacting recyclable materials.

-Manufacturing Plants: To manage and reduce the volume of industrial waste.

-Retail and Distribution Centers: For handling and disposing of packaging materials.

-Waste Management Companies: For efficient waste collection and disposal.

Benefits:

-Space Saving: Reduces the volume of waste, allowing for more efficient storage.

-Cost Reduction: Minimizes transportation and disposal costs by reducing the number of trips required to haul away waste.

-Environmental Impact: Promotes recycling and reduces the environmental footprint by making waste management more efficient.

Considerations When Choosing a Baler:

-Material Type: Ensure the baler is suitable for the specific types of materials you need to compact.

-Capacity: Choose a baler that can handle the volume of material you generate.

-Bale Size: Consider the size of the bales you need for storage and transportation.

-Maintenance and Support: Look for a manufacturer that offers good after-sales service and maintenance support.

If you have specific requirements or need more detailed information, feel free to ask

Video

Parameter

Model | CMS160 | CMS200 | CMS250 | CMS315 |

Chamber Size(mm) | 1500x1000x400 | 1600x1200x450 | 1800x1300x500 | 2000x1400x500 |

Bale Size(mm) | 400x400mm | 450x450mm | 500x500mm | 500x500mm |

Bale Weight(Kg) | 70-150kg | 120-180kg | 150-250kg | 200-300kg |

Power(Kw) | 37kw | 2x30kw | 2x37kw | 2x45kw |

Machine Weight(Kg) | 9820kg | 15360kg | 18720kg | 22580kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

Advantage

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Cycle time can be upto 30 seconds, and 120bales per hour, more efficiently, can help you save lots of money.

> Stable hydraulic system to keep the machine run well.

> Adopts china famous pump to keep baler machine run smoothly.

> Lifelong after services let you have no any concern, get more porfits.

> Enough spare parts with lower cost to keep the machine non-stop.

> Remote Control is optional, can archive automatic operation without worker.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Copper Turnnings |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

|  |  |  |

|  |  |  |

FAQ

> What is cooling system of Baling Aluminum Cans?

Normally speaking, we have types of cooling system, one is water cooling, this cooling system is economical and easy to achive cooling effect, and another type is industrial chiller

> Do you have a customer case of Tin Baling Press Machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> What is warranty term of the Aluminium Scrap Compress Baler?

Within the guarantee period, in the event of any malfunction caused by the quality of the commodity, we provide free components for replacement. Wear parts are exclusive from this warranty. We also provide technical support for the whole lifespan of the machine.

> How much pressing force of Non Ferrous Metal Scrap Baler Machine?

The pressing force of the baler machine is different depends on which model will you need, if you have small capacity, and small bale size and bale weight, then small baler is Ok for you, and the pressing force is small accordingly, such as 100tons or 125tons.

> Do you have a agent of Aluminium Ubc Scrap Packing Machine in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is pump flow of Industrial Metal Compactor machine?

The pump flow of the baler machine is diffent depending on different models, in a word, small models baler machine will have small pump flow, and bigger baler will use bigger pump flow accordingly.

> How to choose your Iron Scrap Compressing Machine correctly?

As for this issues, first, you need to know which model of the baler machine will you need, then you can compare price, quality, services of the baler machine from different suppliers, and at last you will know which supplier is better.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China