A hydraulic scrap baling press is a heavy-duty machine used to compress scrap materials (like metal,...

| Basic Infomation | |

POil Pipe: High Pressure pipe; | Min. Order: 1 Set; Pressure Force:1000-3000KN; |

| Additional Information | |

Machine Weight:4000-10000kg; | HS Code: 8462919000; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

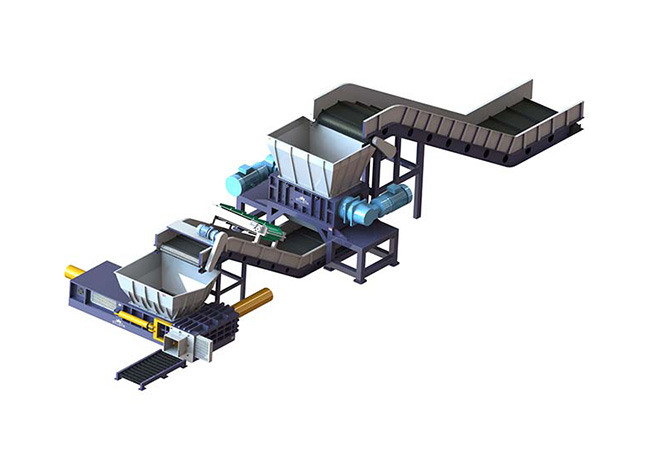

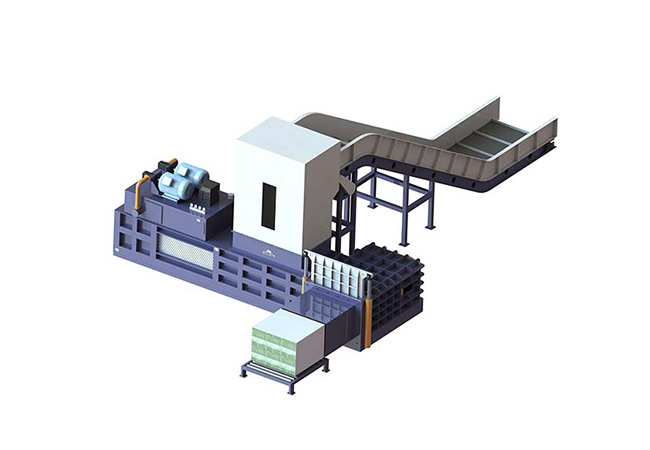

Sisal Fiber Hydraulic Baling Press Machine is a specialized piece of equipment used in the processing and packaging of sisal fiber. Sisal, a type of agave plant, is widely cultivated for its strong and durable fibers, which are used in various applications such as making ropes, mats, and other industrial products.

The hydraulic baling press machine plays a crucial role in compressing these fibers into compact bales, making them easier to store, transport, and handle.

Key Features and Components:

1. Hydraulic System:

- Pump: Provides the necessary pressure to operate the hydraulic cylinders. - Cylinders: These are responsible for applying the compressive force to the sisal fibers. - Valves: Control the flow and direction of the hydraulic fluid, ensuring precise operation.

2. Baling Chamber: - A robust and durable chamber where the sisal fibers are loaded and compressed. - The chamber is designed to withstand high pressures and may be made from materials like steel.

3. Control Panel: - Allows operators to control the machine's functions, including starting, stopping, and adjusting the pressure. - May include safety features and emergency stop buttons.

4. Tying Mechanism: - Once the fibers are compressed, the bale is tied using wire, twine, or straps to maintain its shape. - This can be done manually or automatically, depending on the machine's design.

5. Conveyor System: - Some machines may include a conveyor system to automate the loading and unloading of sisal fibers. - This helps in increasing efficiency and reducing manual labor.

Benefits:

- Efficiency: Reduces the volume of sisal fibers, making them easier to store and transport. - Cost-Effective: Minimizes storage and transportation costs.

- Consistency: Ensures uniform bale sizes and densities, which is important for consistent product quality. - Safety: Modern machines often come with safety features to protect operators.

Applications:

- Agriculture: For baling sisal fibers after harvesting. - Textile Industry: For preparing sisal fibers for further processing into textiles. - Packaging Industry: For creating compact bales for shipping and distribution.

Maintenance and Safety:

- Regular maintenance is essential to ensure the machine operates efficiently and safely - Operators should be trained in the proper use and maintenance of the machine. - Safety guidelines should be followed to prevent accidents and injuries.

If you have specific questions about the operation, maintenance, or any other aspect of a Sisal Fiber Hydraulic Baling Press Machine, feel free to ask.

Parameter

Model | VDD100 | VDD150 | VDD200 | VDD250 |

Bale Size | 1530x360x(400-800)mm | 1350x550x(400-800)mm | 1370x530x(300-600)mm | 1450x550x(300-600)mm |

Bale Weight | 100-200kg | 120-250kg | 100-200kg | 100-200kg |

Motor Power | 18.5kw | 22 | 30 | 37 |

Machine Weight | 3560kg | 4210kg | 5460kg | 6120kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Latest design of the machine to let you use the best the machine all the time.

> Stable hydraulic system to keep the machine run well.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Enough spare parts with lower cost to keep the machine non-stop.

> Weight with one machine is optional, you can save cost of the machine.

> Adopts simple vertical two rams structure, easy to operate and maintain.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

Application

The baler machine can press below materials:

FAQ

> How to choose your Coconut Compressing Fiber Baling Machine correctly?

As for this issues, first, you need to know which model of the baler machine will you need, then you can compare price, quality, services of the baler machine from different suppliers, and at last you will know which supplier is better.

> How can we install the Abaca Fiber Baler Press Machine?

The baler machine is not disassembled when shipping, so you just put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is OK, if you have any questions, you can contact with us any time.

> Do you have a agent of China Hydraulic Jute Press Baling Machine in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is package of Baling Press Machine For Jute?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> Do you have a customer case of Kenaf Fiber Packing Machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> What all do I need to install the Sisal Fiber Baling Press?

After the sisal fiber press machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> How do I decide the model of Coconut Fiber 120Kgs Bailing Press that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China