A hydraulic scrap baling press is a heavy-duty machine used to compress loose scrap materials (like ...

| Basic Infomation | |

Model Series: BPP Series; | HS Code: 8422400090; |

| Additional Information | |

Bale Shape: Cylindrical; | Package: Plastic Films/Nude Package; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

A briquette machine, specifically a copper chip briquetting press, is a piece of equipment designed to compress metal chips, in this case, copper, into compact, manageable blocks or briquettes. This process offers several benefits, including easier handling, reduced transportation costs, and improved recycling efficiency.

Here’s an overview of what you need to know about these machines:

Key Features

1.Compression Mechanism: The core of the machine, which uses hydraulic pressure to compress the loose copper chips into solid briquettes.

2.Feeding System: A mechanism that feeds the copper chips into the compression chamber. This can be manual or automated.

3.Control Panel: An interface for operating the machine, often featuring settings for pressure, cycle time, and other parameters.

4.Safety Features: Includes emergency stop buttons, safety guards, and interlocks to ensure operator safety.

5.Output Size and Shape: The ability to produce briquettes of specific sizes and shapes, depending on the machine's design.

Benefits

1.Reduced Volume: Compressing loose chips into briquettes significantly reduces their volume, making storage and transportation more efficient.

2.Easier Handling: Briquettes are easier to handle and transport compared to loose chips.

3.Improved Recycling Efficiency: Compact briquettes are more suitable for smelting and recycling processes, as they melt more uniformly and efficiently.

4.Cost Savings: Reduces the cost associated with handling, storing, and transporting loose metal chips.

5.Environmental Impact: Reduces the environmental footprint by minimizing waste and improving the efficiency of recycling processes.

Applications

-Metal Recycling Plants: To process and recycle copper chips from various sources.

-Manufacturing Industries: For managing and recycling copper chips generated during manufacturing processes.

-Scrap Yards: To prepare scrap copper for resale or further processing.

Considerations When Choosing a Machine

1.Capacity: Ensure the machine can handle the volume of copper chips you need to process.

2.Pressure Requirements: Different materials and applications may require different levels of pressure.

3.Automation Level: Decide whether you need a fully automated, semi-automated, or manual system.

4.Maintenance and Support: Consider the availability of spare parts and technical support.

5.Energy Efficiency: Look for energy-efficient models to reduce operational costs.

Maintenance

Regular maintenance is crucial to ensure the longevity and efficiency of the briquetting press:

-Lubrication: Regularly lubricate moving parts to prevent wear and tear.

-Cleaning: Keep the machine clean to avoid clogging and ensure smooth operation.

-Inspection: Regularly inspect the machine for any signs of damage or wear.

-Calibration: Periodically calibrate the machine to maintain optimal performance.

If you have specific requirements or need more detailed information, feel free to ask

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

BP800 | Φ200X(100-160) | 13.5-18.6 | 2x45 |

If you have any special requirements, we will customize according to your special needs.

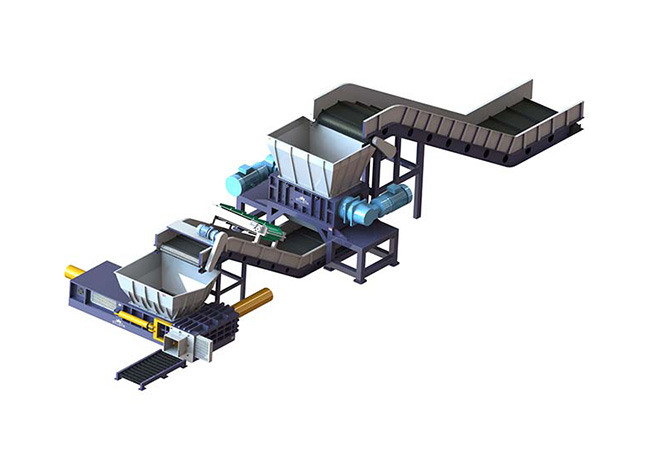

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Output capacity can be up to 200-300bales per hour, more efficient.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

> Adopts high speed structure to reduce cycle time for every one bale.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Adopts china famous pump to keep baler machine run smoothly.

> Schneider electrical components prolong the service life of the machine.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

FAQ

> What all do I need to install the Gaode Waste Cropper Metal Chip Briquetting Machine?

After the briquetting press machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the machine per user manual, or make video call with our engineer.

> What is trade term of Brass turnings briquette machine?

Trade term of the machine are FOB, CIF, CNF, these 3 terms, and we also can per your requirements.

> Do you have a agent of Iron Turning Briquettes Press in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> How to maintain Ruf Briquetting Copper Press Machine?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Do you have a customer case of Metal Chips Briquetting Presses With Ce in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> How to choose your Briquetting Press for Powder Aluminum Alus pan Chips correctly?

As for this issues, first, you need to know which model of the briquetting press machine will you need, then you can compare price, quality, services of the machine from different suppliers, and at last you will know which supplier is better.

> Where to find cheap Brass Chips Briquetting Machine?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China