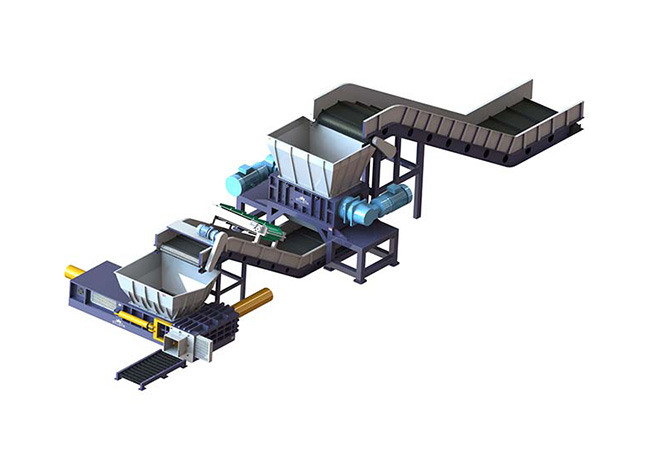

A hydraulic scrap baling press is a heavy-duty machine used to compress loose scrap materials (like ...

| Basic Infomation | |

Color: Ral5013 or Per your requirement; | Min. Order: 1 Set; |

| Additional Information | |

Bale Shape: Cylindrical; | Oil Tank Volume: 600-2400L; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

Brass powder briquette making machine is a specialized piece of equipment used in the metallurgical and recycling industries to compress brass powder into solid, compact briquettes. This process not only makes the material easier to handle and transport but can also be a step in the recycling or reprocessing of brass.

Here are some key points about these machines:

Types of Machines

1.Screw Press: Uses a screw mechanism to compress the powder.

2.Hydraulic Press: Utilizes hydraulic pressure to form the briquettes.

3.Roller Press: Employs two counter-rotating rollers to compress the powder.

Key Features

-High Pressure: Capable of exerting significant pressure to ensure the briquettes are dense and well-formed.

-Adjustable Settings: Allows for customization of briquette size and density.

-Automation: Some models come with automated controls for consistent production.

-Safety Features: Includes safety mechanisms to protect operators and the machine.

Applications

-Recycling: Helps in the efficient recycling of brass by reducing volume and increasing density.

-Manufacturing: Used in the production of brass products where the powder needs to be pre-processed.

-Waste Management: Reduces the environmental impact by minimizing waste and facilitating easier disposal or reuse.

Benefits

-Cost Reduction: Reduces transportation and storage costs by decreasing the volume of the material.

-Easier Handling: Briquettes are easier to handle and transport compared to loose powder.

-Environmental Impact: Reduces dust and improves the overall cleanliness of the work environment.

Considerations

-Material Preparation: The brass powder should be free of contaminants and of uniform particle size for optimal results.

-Maintenance: Regular maintenance is required to ensure the machine operates efficiently and safely.

-Training: Operators should be trained on the proper use and maintenance of the machine.

Manufacturers

-Alibaba: Offers a wide range of briquette making machines from various suppliers.

-GEMCO: Known for their high-quality briquette presses.

-RUF: Specializes in briquette systems for various materials, including metals.

If you are looking to purchase a brass powder briquette making machine, it's important to consider your specific requirements, such as the volume of material you need to process, the desired briquette size, and the available budget. Consulting with a supplier or manufacturer can help you find the right machine for your needs.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP200 | Φ80X(40-70) | 1.2-2.8 | 18.5 |

BP250 | Φ100X(50-80) | 2.3-3.2 | 22 |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

BP800 | Φ200X(100-160) | 13.5-18.6 | 2x45 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

1> Latest design of the machine to let you use the best the machine all the time.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Enough spare parts with lower cost to keep the machine non-stop.

> Adopts high speed structure to reduce cycle time for every one bale.

> Can press varous of metal chips, aluminum shavings, copper granules, bronze chips, brass shavings etc...

> Stable hydraulic system to keep the machine run well.

> Schneider electrical components prolong the service life of the machine.

> Lifelong after services let you have no any concern, get more porfits.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

|  |  |  |

FAQ

> What is warranty time of the Brass turnings baler?

The warranty time of the briquetting press machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> How to maintain Brass Shaving Briquettes machine in China?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Where to find cheap Brass chips Briquetting Press Machine?

You can search the metal chips briquetting press machine machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> What is payment term of High Quality Metal Chips Briquette Press?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How much would Manufacturer Of Metal Chips Briquetting Press , its installation, and training cost me?

The price of baler machine is different according to different bale size, bale weight and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

> What profits can we get from the Cast iron chips briquetting machine?

You need to know price of metal chips, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

> Do you provide video support of Metal Swarf Chips Briquetter?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> What are all the skills required to operate a Brass Swarfs baling machine manufactured by Diloya?

No special skills, just read the user manual carefully before operating the briquetting press machine, if you have any questions, feel free to contact with us, we can help you at any time.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China