A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

SPayment Details:30% as deposit; | Loading Container:40GP or 20GP; |

| Additional Information | |

Cube Size:(250-600)x(250-600)mm; | Transportation:Ocean; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

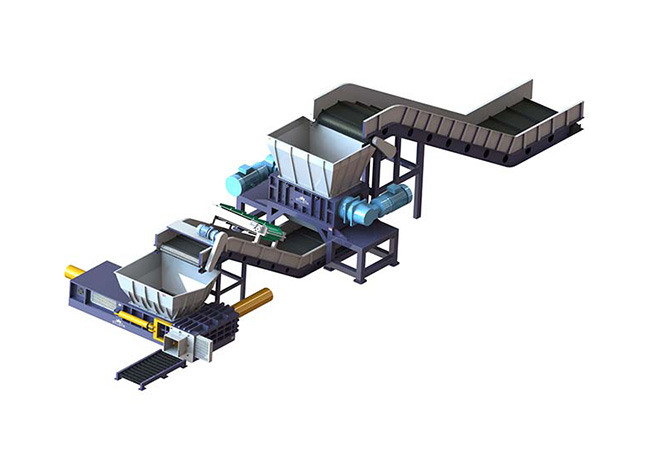

The Auto Scrap metal Compactor Scrap Baler Press is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings, waste cans tins, light metal scrap into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Continuous Tin Cans Scrap Baling Machine,Auto Feeding Scrap Hydraulic Press,How To Compact Stainless Steel Scraps,Tin Can Compression Baler Machine,Hydraulic Aluminum Scrap Press Machine,Horizontal Hydraulic Press For Metal Scrap,Non Ferrous Metal Scrap Baler Press Machine,Baler Machine Recycling With Crane For Metal,Stainless Sheet Metal Compacting Machine.

An industrial hydraulic steel scrap baler is a heavy-duty machine used in the recycling and scrap metal industries to compress and form loose, bulky ferrous (iron-based) and non-ferrous (non-iron based) metals into compact, manageable bales. This process makes it easier to handle, store, and transport the scrap metal, as well as to prepare it for further processing or sale.

Here are some key points about these machines:

Key Features:

1. Hydraulic System: The core of the baler is its hydraulic system, which provides the immense pressure needed to compress the scrap metal. High-pressure hydraulic cylinders push the scrap into a chamber where it is compressed.

2. Compression Chamber: The chamber is where the scrap metal is compressed. It is typically made of durable materials like hardened steel to withstand the high pressures and abrasive nature of the scrap.

3. Bale Size and Shape: The size and shape of the bales can be customized depending on the specific needs of the user. Common shapes include rectangular, cylindrical, or custom configurations.

4. Automation and Controls: Modern balers often feature advanced control systems that allow for automated operation, including loading, compression, and ejection of the bales. These controls can also monitor and adjust the hydraulic pressure to ensure optimal performance.

5. Safety Features: Given the high pressures and moving parts involved, safety is a critical aspect. Balers are equipped with safety guards, emergency stop buttons, and other features to protect operators.

6. Efficiency and Throughput: Industrial balers are designed for high throughput, capable of processing large volumes of scrap metal quickly and efficiently. This is essential for operations that need to handle significant amounts of material.

Applications:

- Recycling Centers: Used to process and manage large volumes of scrap metal from various sources.

- Scrap Yards: To prepare scrap metal for transportation and resale.

- Manufacturing Facilities: For managing and recycling scrap metal generated during production processes.

- Automotive Industry: To handle and recycle scrap metal from vehicle dismantling and manufacturing.

Benefits:

- Space Savings: Compressing scrap metal into bales significantly reduces the space required for storage.

- Transportation Efficiency: Baled scrap is easier and more cost-effective to transport.

- Environmental Impact: Reduces the environmental footprint by making recycling more efficient and reducing the need for raw materials.

- Economic Value: Properly baled scrap metal can fetch higher prices due to its ease of handling and processing.

Maintenance and Care:

- Regular Inspections: Regularly inspect the hydraulic system, seals, and structural components for wear and damage.

- Lubrication: Keep all moving parts well-lubricated to ensure smooth operation.

- Cleaning: Regularly clean the baler to remove debris and prevent contamination.

- Training: Ensure that operators are properly trained to use the baler safely and effectively.

If you have any specific questions or need more detailed information about industrial hydraulic steel scrap balers, feel free to ask!

Please contact with us if you have any questions.

Parameter

Model | CM125 | CM135 | CM160 | CM200 | CM250 | CM315 |

Chamber Size(mm) | 1200x700x600 | 1400x900x800 | 1600x1200x800 | 1800x1400x900 | 2000x1400x1000 | 2500x2000x1200 |

Bale Size(mm) | 300x300mm | 350x350mm | 400x400mm | 450x450mm | 500x500mm | 600x600mm |

Bale Weight(kg) | 40-70kg | 60-100kg | 80-150kg | 130-200kg | 200-300kg | 250-400kg |

Power(mm) | 15kw | 18.5kw | 22kw | 30kw | 2x22kw | 2x37kw |

Machine Weight(kg) | 6250kg | 7380kg | 11540kg | 19840kg | 24580kg | 28420kg |

Machine Size(mm) | 4250x2180x1980 | 4380x2390x2120 | 4780x2560x2150 | 5140x2920x2360 | 5280x2990x2650 | 7380x3850x3260 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

1> Output capacity can be up to 20-30bales per hour, more efficient.

> Lifelong after services let you have no any concern, get more porfits.

> Remote Control is optional, can archive automatic operation without worker.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Stable hydraulic system to keep the machine run well.

> The bale weight ranges from 40kg to 500kg, more options for your choices.

> Adopts simple structure, easy to operate and maintain.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Coppe Wire Scrap |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

|  |  |  |

|  |  |  |

FAQ

> Are you a manufacturer or a trader of Metal Scrap Baling Press low Cost?

We are true manufacturer of scrap metal baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> What bale weight can the Hydraulic Machine Press metal scrap Turkey make?

Normally speaking, the bale weight rangs from 20kg to 300kg, it varys according to your metal scrap and your requirement, we have standard bale size and bale weight, can send you the catalogue for your reference.

> What is payment term of Y81/Q Hydraulic Metal Scrap Baler?

The payment of the baler machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.

> Does Aluminium Wire Scrap Press Machine have PLC control?

Yes, the machine has PLC automatic control, easy to operate and more efficient, and also has manual control, easy to debug and maintain the baler machine.

> What is output capacity of Compress Steel Scrap metal baler?

The machine capacity ranges from 300kg per hour to 3000kg per hour, different models has differnt capacity, small models has small output capacity, and bigger one has big capacity accordingly.

> What profits can we get from the Iron Scrap Baling Recycling Machine?

You need to know price of metal scrap, and price of the bales you sell to metal recycling center or steel manufacturer, then you can know how much profits you will get by this machine.

> How to operate 160Ton Iron Scrap Compactor Machine?

This baler is very simple, just operate per user manual is ok, you can contact with us if you have any questions any time, we can guide you how to operate the baler machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China