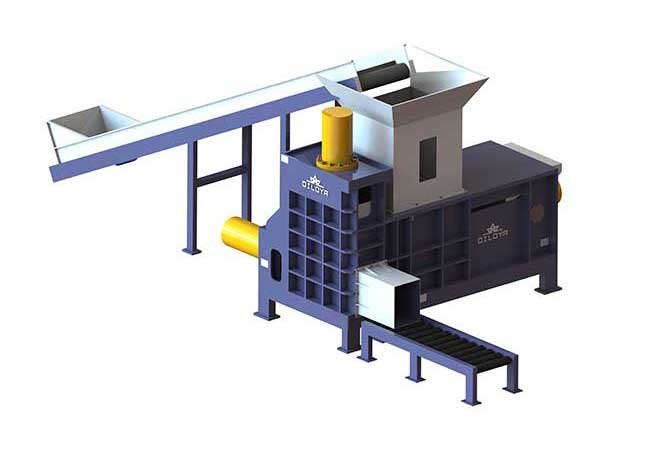

VLB Series Vertical Lifting Chamber Baling Press Machine, mainly compress short fibers, waste yarns,...

| Basic Infomation | |

Hydraulic Force: 200Tons; | Certificate: CE TUV ISO; |

| Additional Information | |

Bale Out Type: Push-Out; | Bale Weight: 800-1200kg; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

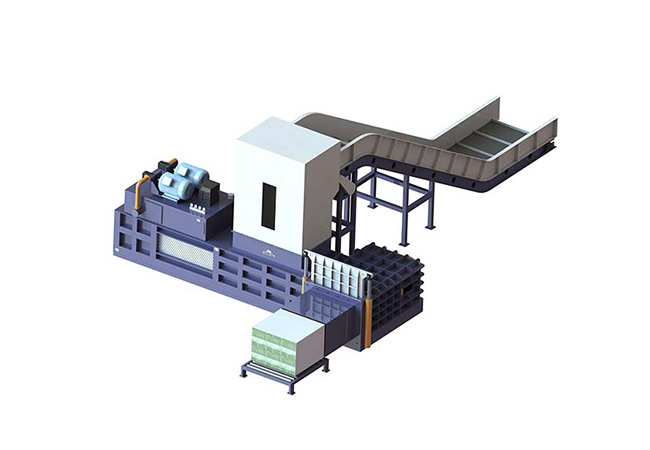

VCB Series Vertical baler is mainly used to compress corn cob granules, rick husks, cotton seed hulls, wood sawdust etc... into a jumbo bag, easy to operate, install and maintain.

A vertical corn cob granules baler is a specialized piece of agricultural machinery designed to compress and package corn cob granules into compact bales. This equipment is particularly useful for farmers and agribusinesses that deal with large quantities of corn cobs, as it helps in the efficient storage, transportation, and utilization of the material.

Here are some key points about vertical corn cob granules balers:

Key Features:

1. Vertical Design: The machine operates in a vertical orientation, which can save space and make it easier to load and unload materials.

2. High Compression: It uses hydraulic or mechanical systems to compress the corn cob granules into dense, uniform bales.

3. Bale Size and Weight: The size and weight of the bales can be adjusted based on the specific needs of the user. Common bale sizes range from 800 to 1200 kilograms.

4. Material Handling: The baler typically includes a hopper for loading the corn cob granules into the compression chamber.

Benefits:

1. Efficient Storage: Compressed bales take up less space, allowing for more efficient use of storage facilities.

2. Easier Transportation: Smaller, denser bales are easier to handle and transport, reducing shipping costs.

3. Reduced Waste: By compressing the granules, the baler minimizes the risk of spoilage and waste.

4. Versatility: Some models can also be used to bale other types of agricultural by-products, such as straw, hay, or other biomass materials.

Applications:

1. Agriculture: Farmers use these balers to manage and utilize corn cob granules, which can be used as animal bedding, fuel, or as a raw material for other products.

2. Bioenergy: Compressed corn cob granules can be used as a renewable energy source in bioenergy plants.

3. Animal Feed: In some cases, the granules can be processed into animal feed, and the baler helps in preparing the material for this purpose.

Maintenance and Operation:

1. Regular Cleaning: The machine should be cleaned regularly to prevent the buildup of debris and ensure smooth operation.

2. Lubrication: Moving parts should be lubricated according to the manufacturer's recommendations to reduce wear and tear.

3. Safety Precautions: Operators should follow all safety guidelines to avoid accidents, including wearing appropriate personal protective equipment (PPE) and ensuring the machine is properly shut down before performing maintenance.

If you are considering purchasing a vertical corn cob granules baler, it's important to evaluate your specific needs, such as the volume of material you need to process, the desired bale size, and any additional features that might be beneficial for your operations. Consulting with a reputable supplier or manufacturer can help you choose the right model and get the most out of your investment.

Video

Parameter

Model | VCB200 |

Chamber Size | 1000x1000x1100mm |

Bale Size | 1000x1000x(800-1000)mm |

Bale Weight | 800-1200kg |

Power | 22kw |

Machine Weight | 4650kg |

If you have any special requirements, we will customize according to your special needs.

Advantage

> Adopts simple vertical two rams structure, easy to operate and maintain.

> The bale weight ranges from 800kg to 1200kg, more options for your choices.

> Output capacity can be up to 10 bales per hour, more efficient.

> Adopts hydraulic lock to promise the safety, stable and durable.

> One Button automatic Control, just need to push one button, you can operate the machine.

> Adopts china famous pump to keep baler machine run smoothly.

> Latest design of the machine to let you use the best the machine all the time.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Stable hydraulic system to keep the machine run well.

> Enough spare parts with lower cost to keep the machine non-stop.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

Application

The baler machine can press below materials:

FAQ

> How much would Vertical corn cob baler, its installation, and training cost me?

The price of baler machine is different according to different bale size and bale weight, as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

> What are all the skills required to operate a hydraulic corn cob baling machine?

No special skills, just read the user manual carefully before operating the machine, if you have any questions, feel free to contact with us, we can help you at any time.

> Are you a manufacturer or a trader of vertical wood sawdust baling machine?

We are true manufacturer of sisal fiber baling machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> Do you provide video support of hydraulic cotton seed hulls vertical baler?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> What is vertical maize corn cob baling machine?

The baler machine is mainly used to compress corn cob, wood sawdust, rick husks, cotton seed hulls into big bales into a jumbo bag with high density, easy to transport and stock, save transport cost, stack cost, convenient for distributor to sell to their end users.

> What is after-services of vertical rick husk baler?

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the baler machine for free, which also include video support, email services, and in a word, we can get everything done.

> What are the service requirements of the vertical corn cob baling machine?

No need special requirements, just contact with our technical team, that is OK, we can get everything done.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China