Do you prvide video support of Automatic Metal Scrap Shear Machine? What is payment term of Alligato...

| Basic Infomation | |

Bundle Size: 200-500mm; | Output Capacity: 40-90bales/Hour; |

| Additional Information | |

Shipping Price: Vary depend machine; | Monthly Throughput: 30-600tons; |

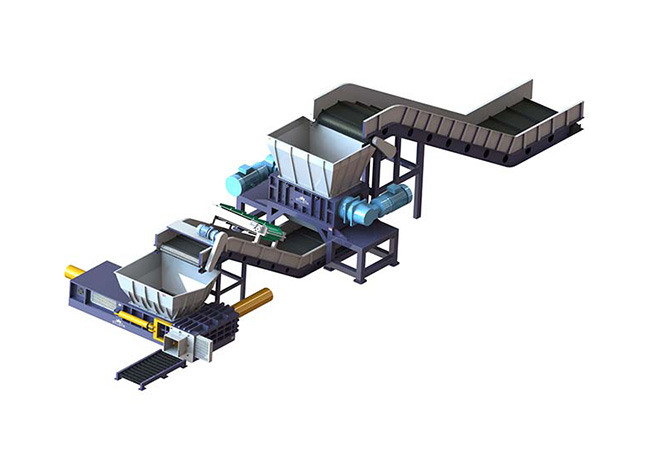

A Non-Ferrous Metal Scrap Pressing Baler Machine is a specialized equipment designed to compress and compact non-ferrous metal scrap materials into dense and manageable bales. Non-ferrous metals include metals that do not contain iron, such as aluminum, copper, brass, lead, zinc, and others. Recycling non-ferrous metals is important for resource conservation and environmental sustainability, and using a pressing baler machine helps in the efficient handling and processing of these materials.

Here's a general overview of how a Non-Ferrous Metal Scrap Pressing Baler Machine typically works:

1. **Loading**: Non-ferrous metal scrap is loaded into the baler manually or through a conveyor system.

2. **Compression Chamber**: The material is fed into a compression chamber where a hydraulic ram applies pressure to compress the non-ferrous metal scrap.

3. **Hydraulic System**: Similar to the aluminum scrap hydraulic baler, the non-ferrous metal baler uses a hydraulic system to generate the force needed for compression. A hydraulic pump, hydraulic fluid, and hydraulic cylinders work together to move the ram and apply pressure to the scrap material.

4. **Baling Process**: As the hydraulic ram exerts force, the non-ferrous metal scrap is compressed into a tightly packed, dense bale.

5. **Bale Tying or Strapping**: Once the compression process is complete, the bale is often tied or strapped to maintain its shape during handling and transportation.

6. **Bale Ejection**: The finished bale is then ejected from the machine and can be stacked or transported for further processing or recycling.

These machines are designed to handle a variety of non-ferrous metals in different forms, such as sheets, wires, tubes, and more. The specific design and features of a Non-Ferrous Metal Scrap Pressing Baler Machine may vary based on the type and volume of materials it is intended to process.

Using baler machines for non-ferrous metal recycling contributes to the efficiency of scrap metal recycling operations, reduces storage space requirements, and facilitates the transportation of materials for recycling facilities. It also aids in cost-effective and environmentally responsible handling of non-ferrous metal scrap.

Video

Parameter

Model | CMS100 | CMS125 | CMS160 | CMS200 | CMS250 | CMS315 |

Bale Size | 250x250mm | 300x300mm | 350x350mm | 400x400mm | 450x450mm | 500x500mm |

Bale Weigh | 15-25kg | 20-40kg | 35-70kg | 60-110kg | 120-180kg | 200-350kg |

Chamber Size | 1200x700x250mm | 1400x800x300mm | 1500x1000x350mm | 1800x1200x400mm | 2200x1400x450mm | 2500x1400x500mm |

Motor Power | 22kw | 30kw | 37kw | 30x2kw | 37x2kw | 37x3kw |

Machine Weight | 5630kg | 7680kg | 11370kg | 16500kg | 19450kg | 27650kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Output capacity can be up to 30-60bales per hour, more efficient.

> Remote Control is optional, can archive automatic operation without worker.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Adopts Two rams structure to keep high bale density.

> Enough spare parts with lower cost to keep the machine non-stop.

> Latest design of the machine to let you use the best the machine all the time.

Application

The baler machine can press below materials:

FAQ

> How can i know you are a manufacturer or trader of Stainless Sheet Metal Press Compactor?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> How to install Aluminum Can Compactor?

For small baler machine, we will not disassemble it when shipping, you just need to add hydraulic oil and connect to the electrical power, then operate per user manual, that is Ok, for bigger one, we will make detail marks when disassembling the machine, you just only need to assemble the machine per marks, that is alright; and you can contact with our technical team when you have any problems.

> How long of warranty time of Ring-Pull Cans Packing Baler?

The warranty time is 14 months, in another word, 1 year from date of shiping the machine.

> What is trade term of Tinplate Scrap Compressor Machine?

Trade term of the baler machine are FOB, CIF, CNF, these 3 terms, and we also can per your requirements.

> Do you have a agent of Stainless Steel Balers in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> How do I decide the model of Ring-Pull Cans Compress Baler that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> What all do I need to install the Non Ferrous Metal Scrap Press Machine?

After the metal scrap baler machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China

Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China