What is price of China Supplier Used Beverage Cans Compress Baler? How to maintain High Speed Alumin...

| Basic Infomation | |

Steel Plate thickness: 12-30mm; | Remote Control: Optional; |

| Additional Information | |

Trade Term: FOB CIF CNF; | Oil Tank Volume: 800-3000L; |

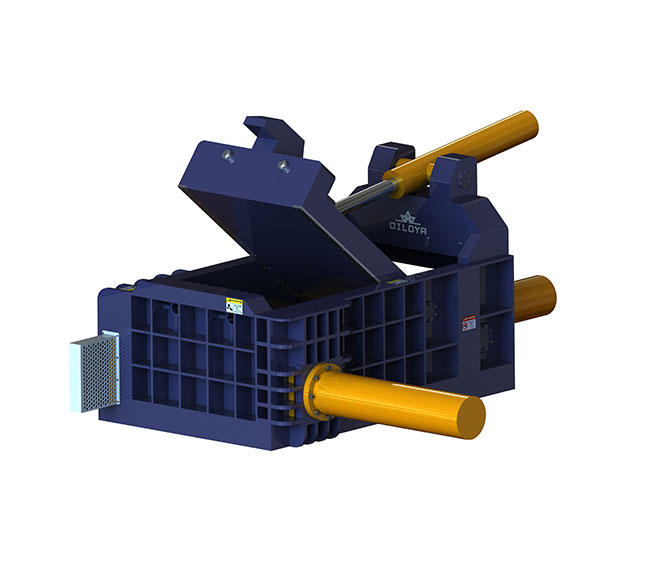

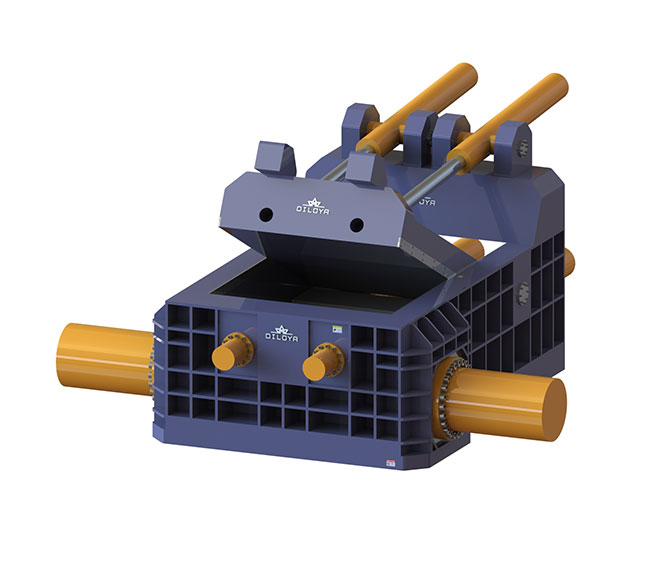

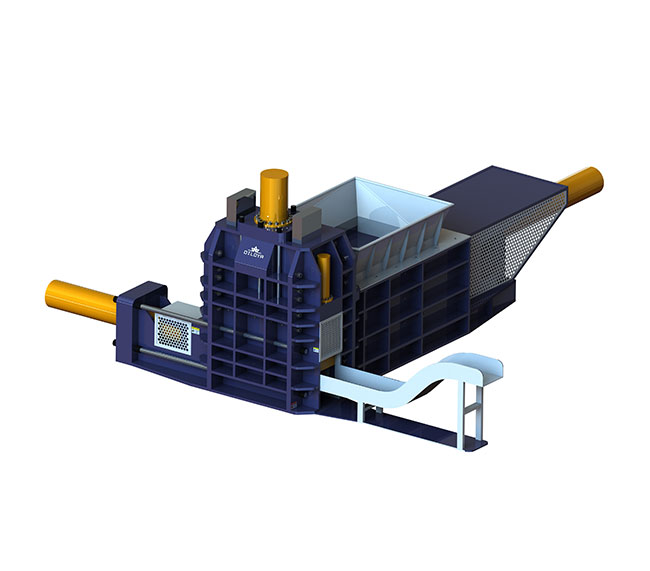

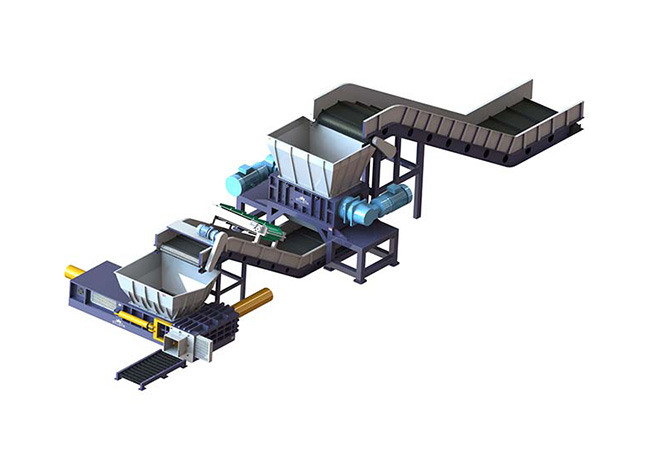

The High Speed Tins Cans Baling Machine is mainly compress the waste cans tins, ubc cans, stainless steel scrap, metal chips, mixed aluminum scrap into small bales with high density for steel manufacturer to remelt again, it is easy to transport, stock, can improve the rate of steel melting , it has other names such as Low Price Aluminum Tins Packing Baler,Fast Ring-Pull Cans Compactor,Automatic UBC Compactor,Aluminium Ubc Cans Baling Machine,125Ton Pop Cans Baling Press,Low Price Waste Cans Compactor,Hydraulic Zip Top Cans Baler With Conveyor,Hight Speed Pop-Top Cans Compress Baler,Small Waste Cans Baler With Conveyor.

We not only have these baler machine, but have other machines such as Hopper Feed Zip Top Cans Press Baler,Heavy Duty Used Metal Baling Press,250Ton Metal Scrap Press Baler,160Ton Scrap Metal Baling Press,400Ton Metal Scrap Baling Press,Aluminium Cans Baling Press Baler,Y81T Iron Scrap Baling Machine,China Supplier Waste Cans Recycling Baler,Big Volume Hopper Aluminum Tins Baler,Scrap Steel Baler Machine South Africa,200Ton Light Metal Compactor,Vertical Scrap Aluminum Profiles Press Baler,250Ton Metal Scrap Compress Baler,Automatic Metal Scrap Baling Machine,Turn Out Used Metal Compress Baler,125Ton Pop Cans Compress Baler,Two Ram Aluminum Scrap Baling Press,Y81F Waste Steel Compactor,Metal Baler Cans,100Ton Pop Cans Baler,Metal Baler Remote Controls,200Ton Light Metal Press Baler,Big Volume Hopper Aluminum Cans Baler,Remote Control Steel Scrap Compress Baler,Big Steel Wire Compactor,315Ton Steel Scrap Press Baler,Low Price Zip Top Cans Baling Press,Forward Out Light Metal Baling Machine,Two Ram Tinplate Compress Baler,500Ton Scrap Metal Baling Machine,Remote Control Steel Scrap Compactor Machine,Big Iron Scrap Compactor Machine,Scrap Metal And Baler,100Ton Tins Cans Recycling Baler,Metal Scrap Baler Machine,Rebar Hydraulic Press baler,Fast Used Beverage Cans Compactor Machine,Jiangsu Factory Iron Scrap Baling Press,Fast UBC Compress Baler,Hopper Feed Stainless ScrapRecycling Baler etc... Please contact with us if you have any questions.

Video

Parameter

Model | CMS125 | CMS160 |

Bale Size | 300x300mm | 350x350mm |

Bale Weigh | 20-40kg | 35-70kg |

Chamber Size | 1400x800x300mm | 1500x1000x350mm |

Motor Power | 30kw | 37kw |

Machine Weight | 7680kg | 11370kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

Advantage

>> Schneider electrical components prolong the service life of the machine.

> Adopts Two rams structure to keep high bale density.

> The bale weight ranges from 20kg to 300kg, more options for your choices.

> Latest design of the machine to let you use the best the machine all the time.

> Lifelong after services let you have no any concern, get more porfits.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

Application

The baler machine can press below materials:

FAQ

> What is Horizontal Metal Baler?

The baler machine is mainly used to compress light metal scrap, stainless steel scrap, aluminum scrap, waste tins cans etc into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for recycling center or steel manufacturer to melt again, improve the rate of steel melting.

> Are you a manufacturer or a trader of Hydraulic Pressing Machine Of Cans?

We are true manufacturer of scrap metal baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> Is your price of Tin Scrap Baler Machine competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as tf baler, eco baler, wanshida baler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> How much is the shipping cost of Hopper Feed Scrap Metal Balers?

The shipping cost is varying over time,and different models of baler machine will need different containers to hold, if peak season and bigger models, the shipping cost will be higher, and on the contrary, the cost will be lower.

> Do you have a customer case of Aluminium Scrap Horizontal Baling Machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> How to install Cans Baling System Plant?

For small baler machine, we will not disassemble it when shipping, you just need to add hydraulic oil and connect to the electrical power, then operate per user manual, that is Ok, for bigger one, we will make detail marks when disassembling the machine, you just only need to assemble the machine per marks, that is alright; and you can contact with our technical team when you have any problems.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China

Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China